Eco-Industrial Park Colombia

PARKACTIVE’s Circular Business Model: Nurturing Sustainability

At PARKACTIVE, our circular business model serves as the bedrock of our commitment to sustainability. This holistic approach aims to align side-stream operations seamlessly within our ecosystem, creating a harmonious cycle of resource utilization. Central to this model is the pursuit of zero-waste circularity, where each by-product undergoes transformation, giving rise to additional valuable co-products.

Five Operating Elements of our Eco-Industrial Park Concept:

Self-Sustainable Power Generation

Co-generation of hot water plays a pivotal role in our eco-system, utilised for biomass drying and the distillation process.

Waste Treatment

Organic waste and plastic waste are ingeniously repurposed into valuable resources:

- Organic waste transforms into biogas and fertiliser

- Waste plastics are converted into recycled polymers and synthetic diesel

Processing Units

Our processing units are versatile and comprehensive, handling a range of raw materials and side streams:

- Wood processing for industrial purposes (Sawmill, Pellet line, Pallet line, Fiber line)

- Biogas production

- Distillation processes

- Fruit processing (Juice, Concentrate, Oil)

- CO2 extraction for various applications (Oil, Medical & Cosmetic base products)

Forestry

We sustainably manage Eucalyptus and Bamboo, with Eucalyptus logs serving industrial pallet manufacturing and pole production for passion fruit plantations.

- Felling residues, combined with sawdust and woody by-products from fruit processing, contribute to pellet production

- Bamboo serves as alternative poles for plantations and a supplementary feedstock

Farming

Napier Grass is a dual-purpose crop, producing energy through juice-to-biogas conversion and woody-biomass pelletisation

- Industrial Hemp acts as a versatile crop, contributing to processing feedstock and serving as energy biomass

Part of an ongoing major development

PARKACTIVE Colombia will be implemented next to „Puerto Antioquia“, where existing businesses are operating.

The Eco-Industrial Park Colombia is designed to be generating enough energy for the park and the newly built port, as well as providing waste treatment capacities for the entire region. It is also generating financial return through forestry, agriculture, food processing and carbon credit.

Benefiting from major highway construction projects, the port is set to unlock greater road connectivity, lower transportation costs for exporters and importers into Colombia. Such proximity to the port underpins the very importance of Parkactive’s industrial park concept and the potential to derive many benefits we envisage.

Not Starting from Scratch – our Eco-Industrial Park in Colombia

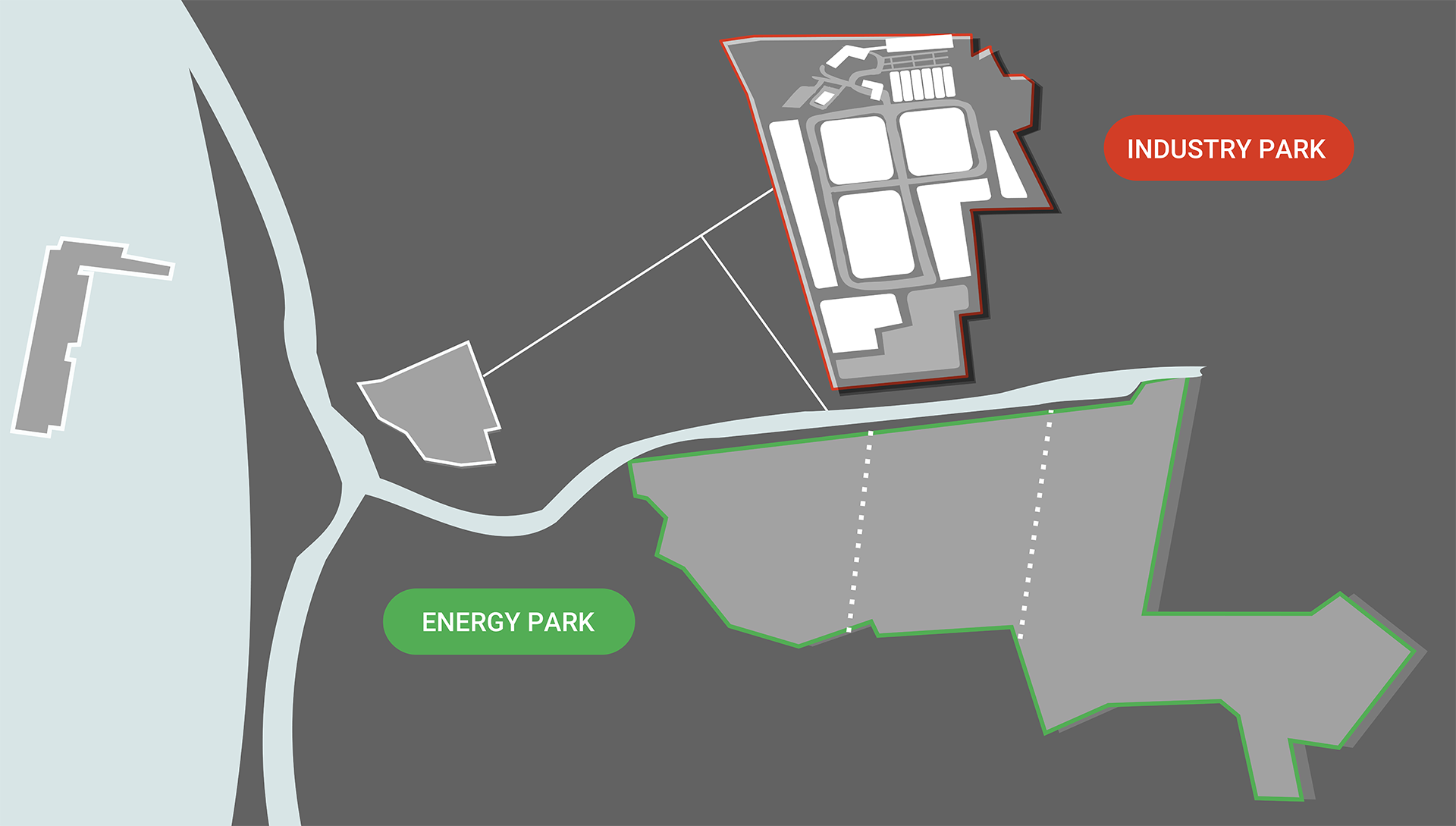

The site of the eco-industrial park will be developed in a dynamic area in Colombia, where banana growers are exporting 30 millions boxes per year and where several companies are already operating. It will encompass 50 hectares for clients, predominantly within the agribusiness, and features a 150-hectare energy park, generating power (50MW) and treating and recycling organic and plastic wastes. The park also includes cultivating, harvesting, processing and selling fruits. It is expected that construction will begin in 2025.

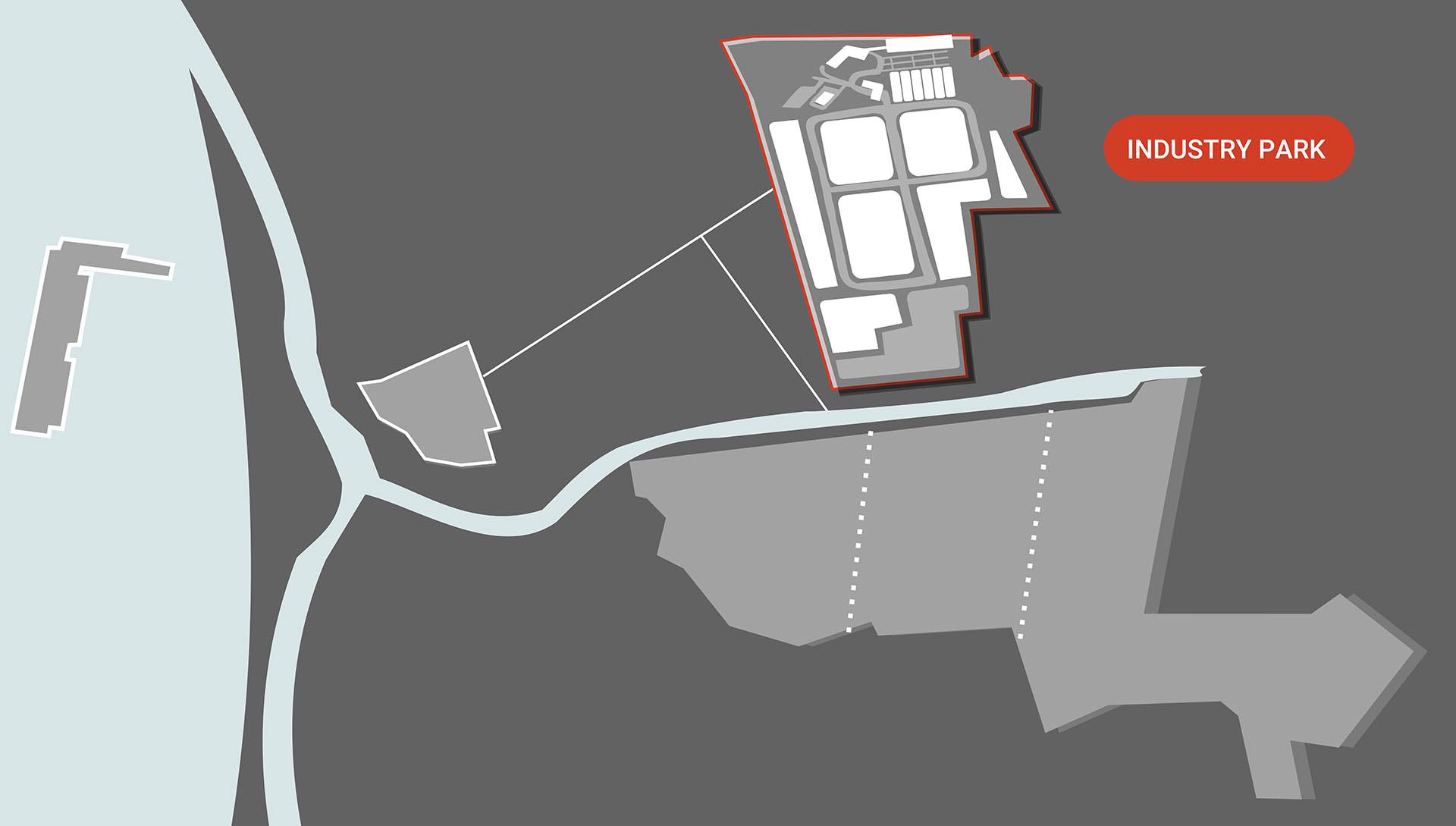

Industry Park

All industrial processes are carried out in this 49-hectare area. The two operating companies that are already located here are a great advantage: a factory for processing fruits and the CFS logistics company. We also offer our customers the possibility of renting factory space, offices and warehouses.

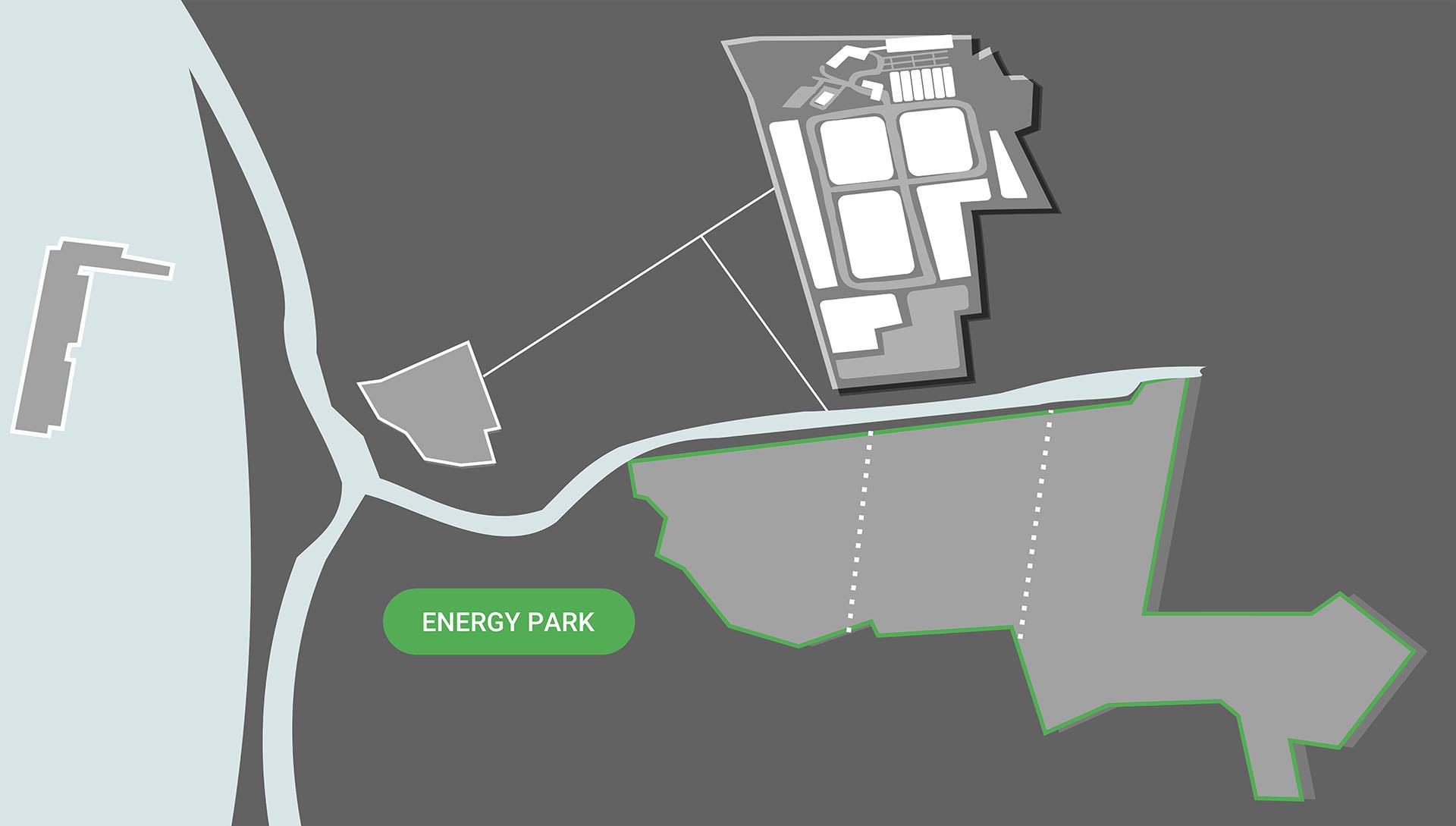

Energy Park

This site will have a total area of 150 ha. It will be used for activities that require storage and isolation due to dusts and odours. There are also two active companies located here: the shipyard with an onshore and offshore terminal and a plastics factory. As with the industrial park, access and exit will be by road or canal to enable short transport routes.

Circular Business Model by Side-Streaming

PARKACTIVE’S circular business model:

1. Keep the side-stream operations in line with our eco-system.

2. Find the right critical mass in feedstock and residues.

Zero-waste circularity

It is about implementing a complete solution where each

by-product is transformed to create additional co-products.